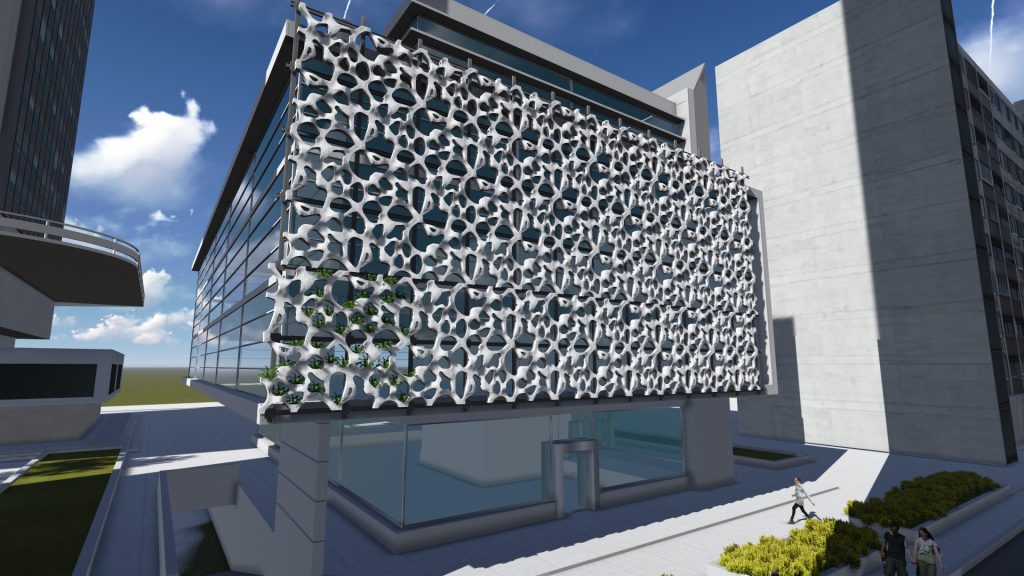

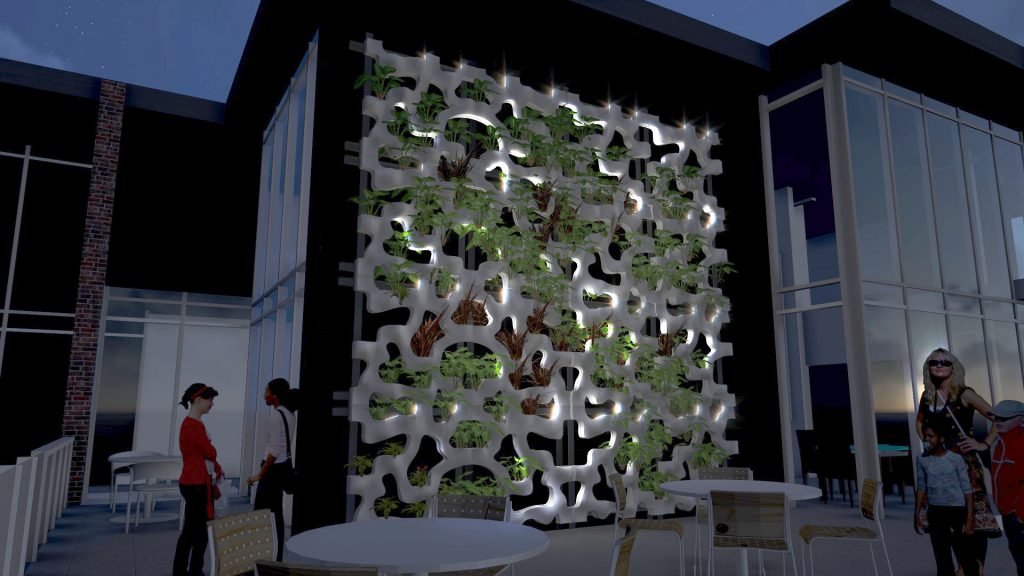

HydroSkin explores the building façade beyond its traditional use as a barrier between in and out, transforming it into a multi-functioning, living, breathing object. Researched and designed as a module, the hydroponic prototype addresses three needs: attachment to an existing façade, horticultural life cycle, and illumination.

Existing Facade Attachment

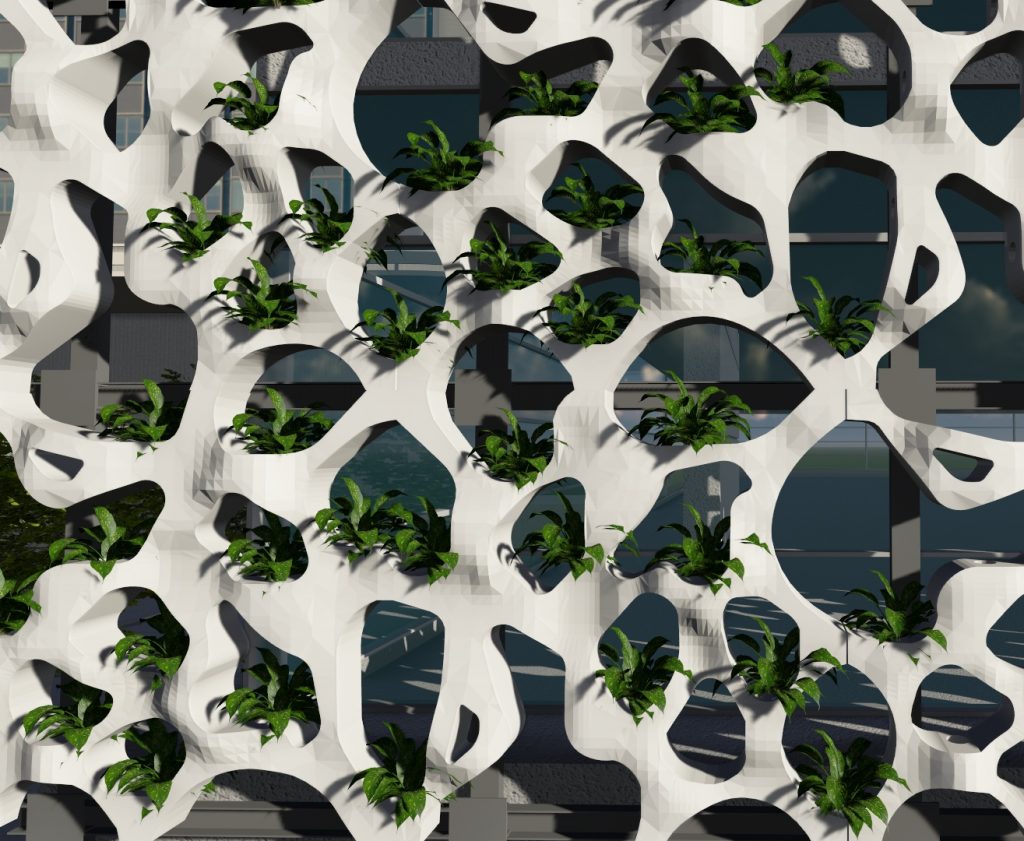

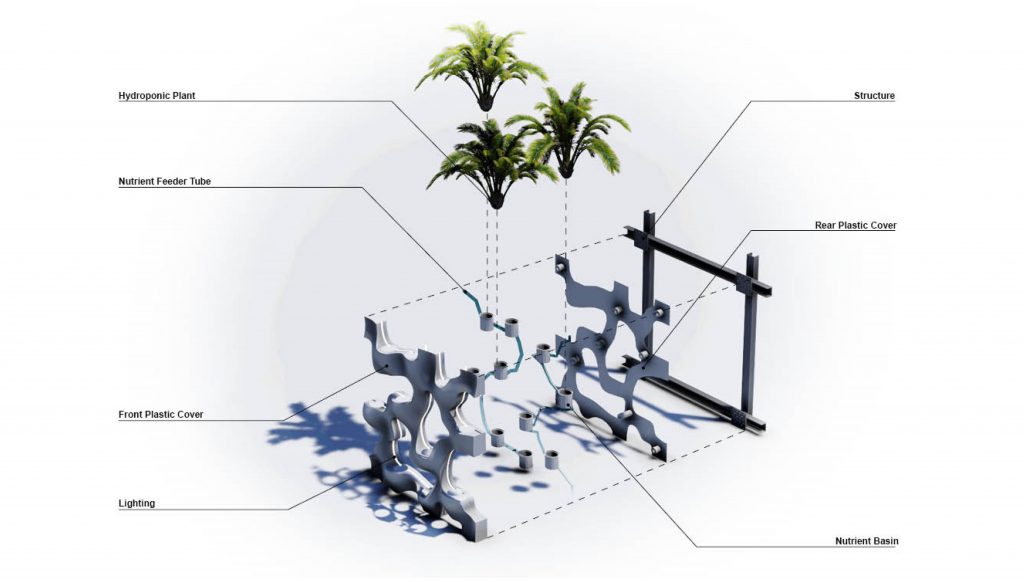

Research shows that modularity of form is paramount for future replication and a consistent aesthetic. Mounted to a grid attached to an existing façade, the form contains cell-like openings, each lined with a planter pot. These pots are interconnected through a network of feeder tubes within the form that lead back to a nutrient reservoir, providing sustenance while maintaining a clean aesthetic.

Horticultural Life Cycle

HydroSkin acts as a vertical farm while reducing pollution and energy consumption. The incorporated hydroponic system is designed to be fed manually, or by rainwater and building condensate discharge. The HydroSkin or Hydro Wall can be an income generator for the building owner as it can either be rented or considered an amenity to the building tenants and/or residents.

Illumination

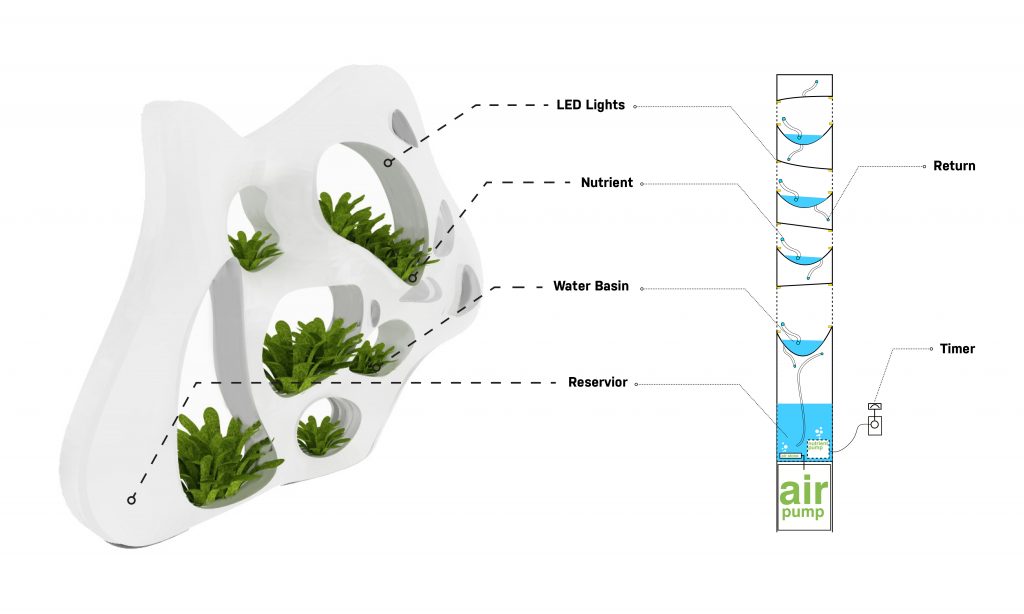

The hydroponic plants grow along with the season. To ensure plants receive enough light, HydroSkin incorporates contouring LED light strips at the perimeter of each plant container opening. This supplemental lighting assures an abundance of stocky green seeding, and enhances the building’s nighttime and cold season aesthetic. The lighting strips can be connected within an individual 5’x5’ module and from one module to another.

Hydroponic Design

Hydroponics is a method of growing plants that utilizes water as the means of transporting mineral nutrients without using soil. Plants are grown with their roots in a nutrient-rich solution that is oxygenated by an air pump and allows for precise control of nutrient flow to the plants. When combined with a porous growing medium, hydroponics makes it possible to reap higher yields faster than traditional growing methods. The concept for maintaining hydroponic plants is simple. Plants have five basic needs, each accounting for 20 percent of their growth potential. Meeting all five needs fully results in maximum plant growth. While hydroponics may not be the only method of urban farming on a building exterior, it is one of the most advanced and efficient techniques. It allows for the repurposing of clean condensate or rain water that would otherwise go unused, and results in a clean, soil-free, growth-maximizing system.

HydroSkin, like any other hydroponic circuit, consists of a reservoir for storing water and adding nutrients. This reservoir benefits from two pumps: a submersible water pump inside the reservoir to circulate nutrient-rich water to all participating planters, and an air pump outside the reservoir to maintain water oxygen levels. Each plant is placed into a net-pot which lives in its own respective container. The reservoir is connected to the containers through a series of rubber tubes responsible for circulating the water to the plants and back. Reservoir PH and EC levels are monitored and adjusted to assure consistent healthy plant growth.

Structural Design

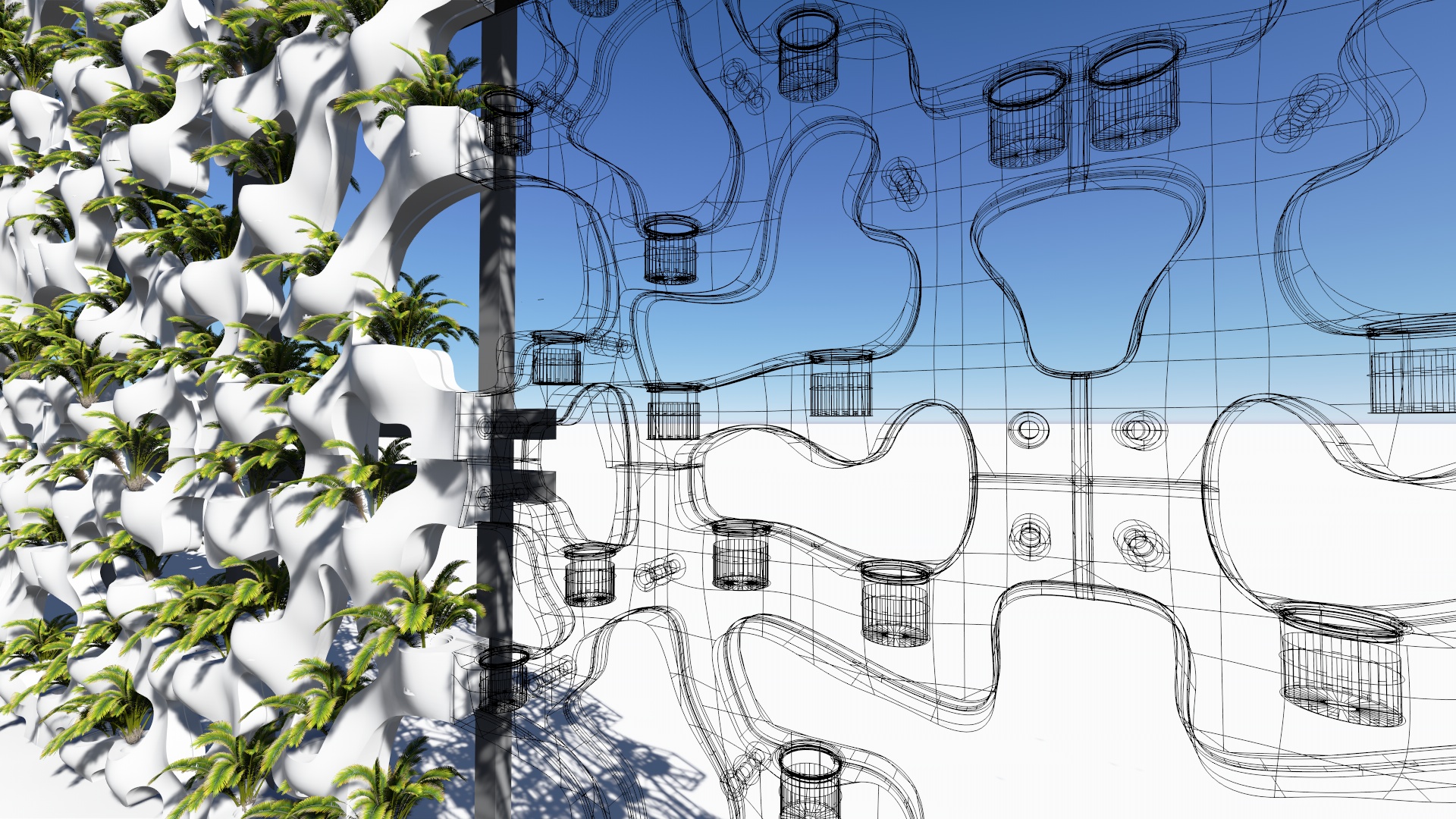

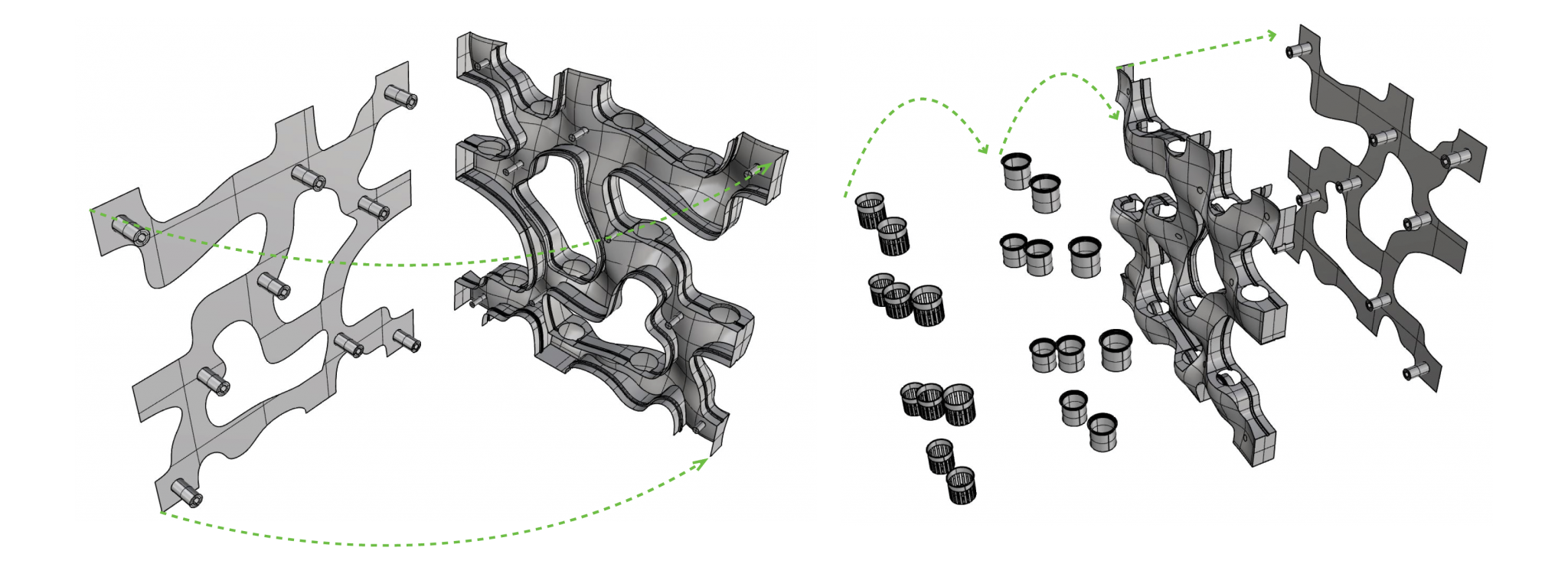

HydroSkin is designed as a system of connected modules to allow for convenience and flexibility in production. It consists of a flat back panel and a dynamic front panel, with electrical and hydroponic contents hidden between the two. The 5’x5’ module connects to adjacent panels at 8 separate nodes, with electrical and plumbing connections assembled vertically at the top and bottom of each. The dynamic design creates a sculptural form and prevents repetitiveness when used over large areas. Each module is prefabricated, with its supporting grid structure installed on-site.

Construction

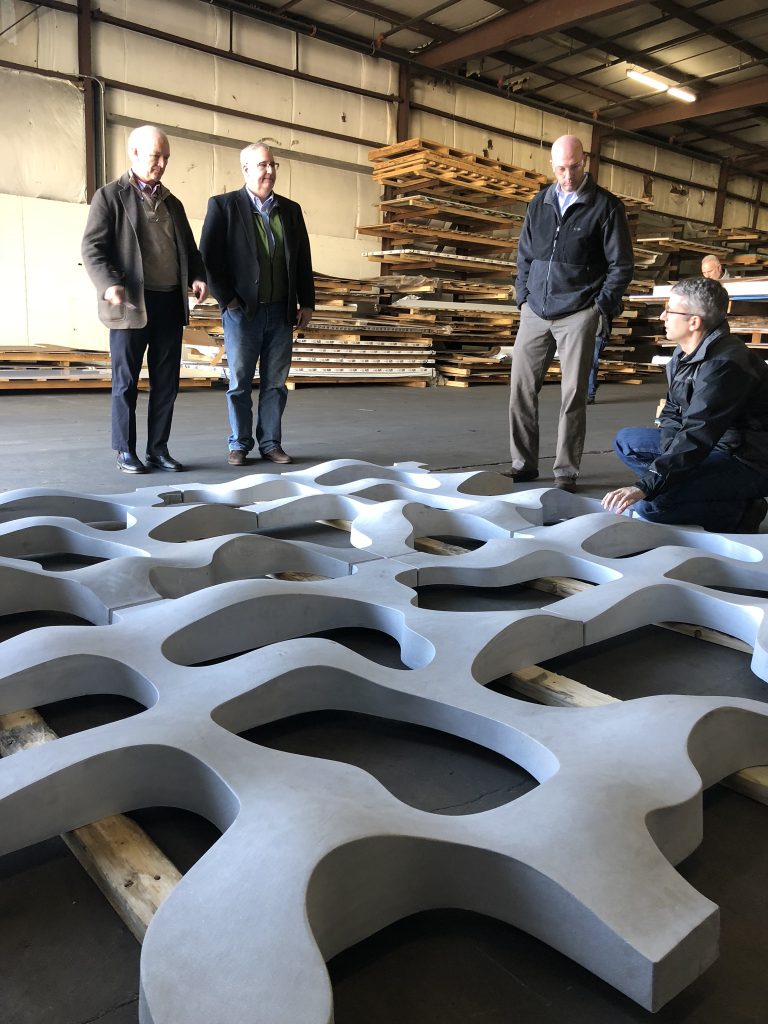

In 2015, the Hickok Cole HydroSkin team began working to prototype the design in partnership with Curtainwall Design Consulting (CDC) and Metalwërks USA. During the process, the team tested a variety of building materials, selecting aluminum for its ability to meet the design’s functionality and aesthetic specifications. Fabrication began at the beginning of 2017 in conjunction with thorough testing of the hydroponic and lighting systems to ensure they functioned efficiently. This testing incorporated a variety of herbs and lettuces to see how different plants responded to the system.

The first HydroSkin prototype was installed at Hickok Cole’s Georgetown headquarters in May 2018.

What's Next?

The HydroSkin prototype was developed in partnership with Metalwërks USA and Curtainwall Design Consulting. We’re currently exploring the re-installation of our HydroSkin prototype at our new headquarters in DC’s Union Market District.